- Out-of-Stock

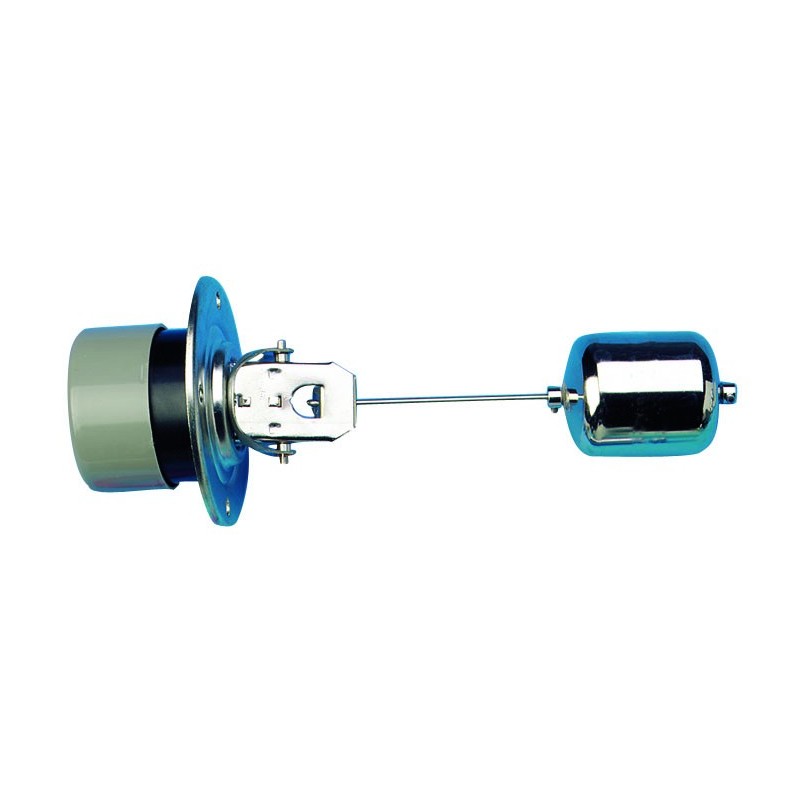

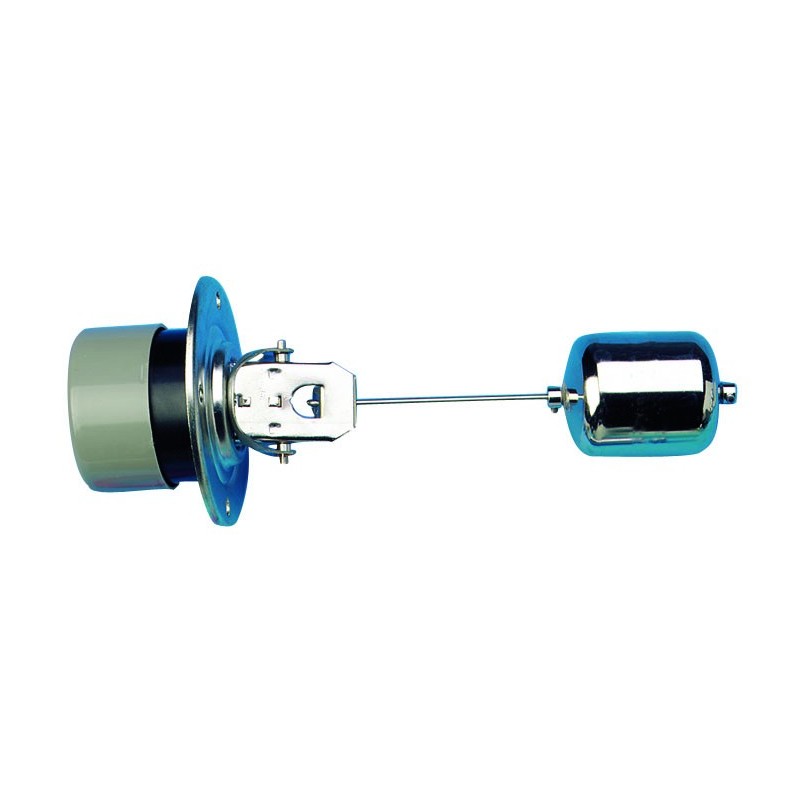

The magnetic transfer from the movement of the float to the contact element ensures perfect sealing.

The total angular movement of the float arm is 34°. The movement necessary to tilt the switch is approximately 28° (differential).

The float, immobilised by two adjustable rings, can be positioned at a distance L from the articulated joint articulation O. This distance L determines the difference in level necessary to trip the contact; this equals L x 0.5. However the float should be capable of travelling a total distance equal to L x 0.6.

These relations are valid for symmetrical movement of the float arm with respect to the horizontal axis XY (Lmin = 90 and Lmax = 265). On request, possibility of longer float arm (600 mm maximum) to obtain a differential greater than 130 mm.

Specification |

|

|

Materials |

: Housing, wherein the electrical switch is located, is made of bakelite. |

|

|

: Cap covering the connecting terminals is made of polystyrene. |

|

|

: Hinge pin, setting screw, stainless steel float arm |

|

|

: Bichromated cadmium magnet |

|

|

: Nickel-plated brass Float |

|

|

: All other parts are made of duclanised brass. |

|

T° max. |

: +100°C maximum (for the controlled liquid). |

|

Protection |

: IP30 (outside of the housing to the tank). |

|

Pressure |

: 1 bar maximum (inside the container). |

|

Code notice |

Montage |

Particularité & Modèles |

|

Horizontal |

H12AN / H12ANS / H12A2 / H12L / H12H |

|

|

Vertical |

H12C / H12E / H12G |

|

|

Horizontal |

Version TOUT INOX |

|

|

Horizontal |

Certifié ATEX |